В современном мире пищевая промышленность сталкивается с растущими вызовами: увеличение спроса на продукты питания, ужесточение требований к безопасности и качеству, а также необходимость снижения издержек. Автоматизация становится незаменимым инструментом для решения этих задач, обеспечивая повышение эффективности, улучшение качества продукции и сокращение человеческого фактора. В этой статье мы подробно рассмотрим, как автоматизация трансформирует пищевое производство, её ключевые аспекты, преимущества и будущие перспективы.

Введение в автоматизацию пищевой промышленности

Автоматизация в пищевой промышленности – это процесс внедрения технологий, таких как робототехника, системы управления и искусственный интеллект, для автоматического выполнения задач, которые ранее требовали ручного труда. Это не просто тренд, а необходимость, driven by the need for consistency, speed, and precision. Исторически пищевая отрасль была одной из наименее автоматизированных, но с развитием технологий ситуация rapidly changes.

Например, в прошлом веке основные процессы, такие как упаковка и сортировка, выполнялись вручную, что приводило к высокому уровню ошибок и низкой производительности. Сегодня автоматизированные линии могут обрабатывать thousands of units per hour with minimal human intervention. This shift is crucial for meeting global food demands, especially in the context of population growth and urbanization.

Кроме того, автоматизация помогает comply with strict regulatory standards, such as those set by organizations like the FDA or EU food safety agencies. By reducing human contact, it minimizes the risk of contamination and ensures that products meet hygiene requirements. This is particularly important in sectors like dairy, meat, and baked goods, where safety is paramount.

В целом, автоматизация – это не просто about replacing labor; it's about enhancing整个 production ecosystem. It enables real-time monitoring, data analysis, and adaptive control, which are essential for maintaining high standards in a competitive market.

Ключевые технологии автоматизации в пищевом производстве

Автоматизация в пищевой промышленности relies on a variety of technologies, each playing a specific role in optimizing processes. Let's explore some of the most impactful ones.

Роботизация и автоматизированные системы

Роботы are increasingly used for tasks such as picking, packing, palletizing, and even cooking. In food production, collaborative robots (cobots) are gaining popularity because they can work safely alongside humans. For instance, in a bakery, robots can handle delicate items like pastries without damaging them, while in a meat processing plant, they can perform precise cuts that improve yield and reduce waste.

Advanced vision systems allow robots to identify and sort products based on size, color, or defects. This is crucial for quality control, as it ensures that only the best items reach consumers. Moreover, robotic arms equipped with sensors can adapt to variations in raw materials, making production more flexible and efficient.

Системы управления и IoT

Интернет вещей (IoT) enables connected devices to communicate and share data in real-time. In food production, IoT sensors can monitor temperature, humidity, and other environmental factors that affect product quality. For example, in cold storage, IoT systems can alert operators if temperatures deviate from safe ranges, preventing spoilage and ensuring compliance with safety standards.

Системы управления, такие как SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution Systems), integrate data from various sources to provide a holistic view of the production process. They allow for remote monitoring and control, reducing the need for on-site personnel and enabling quicker responses to issues. This leads to higher uptime and better resource utilization.

Искусственный интеллект и машинное обучение

AI and machine learning are revolutionizing food production by enabling predictive maintenance, quality assurance, and demand forecasting. For instance, AI algorithms can analyze historical data to predict when equipment is likely to fail, allowing for proactive maintenance that avoids costly downtime. In quality control, machine learning models can detect anomalies in products, such as foreign objects or imperfections, with higher accuracy than human inspectors.

Additionally, AI can optimize supply chain management by predicting demand fluctuations based on factors like seasonality or market trends. This helps in reducing inventory costs and minimizing waste, which is a significant issue in the food industry where perishability is a constant challenge.

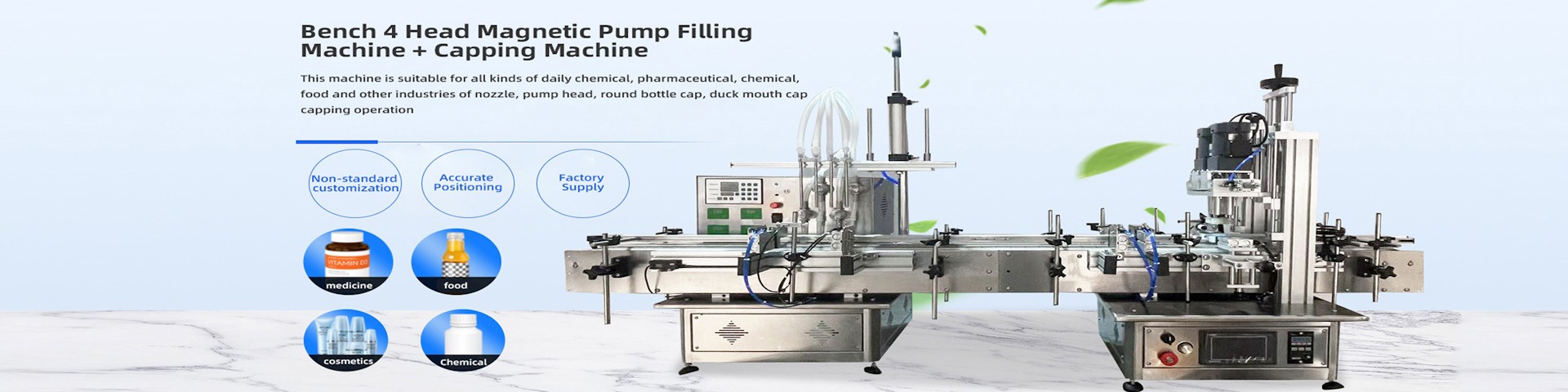

Автоматизация упаковки и логистики

Упаковка is a critical area where automation shines. Automated packaging lines can handle various formats and materials, adapting quickly to different product types. This flexibility is essential for manufacturers who produce multiple SKUs. For example, a single line can switch from packaging cereals to snacks with minimal reconfiguration, saving time and reducing costs.

In logistics, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are used to transport materials within facilities. They improve efficiency by reducing manual handling and minimizing errors in inventory management. This is particularly beneficial in large warehouses where speed and accuracy are crucial for meeting delivery schedules.

Преимущества автоматизации для эффективности и качества

Автоматизация brings numerous benefits that directly impact efficiency and quality in food production. Let's delve into the key advantages.

Повышение производительности и сокращение издержек

One of the most immediate benefits of automation is increased productivity. Automated systems can operate 24/7 without fatigue, leading to higher output rates. For example, an automated bottling line can fill and cap thousands of bottles per hour, far exceeding what human workers could achieve. This not only boosts production capacity but also reduces labor costs, as fewer workers are needed for repetitive tasks.

Moreover, automation minimizes waste by ensuring precise measurements and consistent processes. In food production, even small variations can lead to significant losses. Automated systems control parameters like ingredient proportions and cooking times with high accuracy, resulting in less rework and spoilage. This directly improves the bottom line by reducing material costs and enhancing yield.

Улучшение качества и consistency продукции

Consistency is key in food production, as consumers expect the same taste, texture, and appearance every time they purchase a product. Automation ensures that processes are repeatable and controlled, eliminating human errors that can lead to variations. For instance, in baking, automated ovens maintain exact temperatures and timing, producing uniformly baked goods.

Quality control is also enhanced through automated inspection systems. Cameras and sensors can detect defects that might be missed by the human eye, such as minor discolorations or packaging flaws. This not only improves product quality but also enhances brand reputation by reducing the likelihood of recalls or customer complaints.

Повышение безопасности и соответствия стандартам

Food safety is a non-negotiable aspect of production. Automation reduces the risk of contamination by minimizing human contact with food products. In environments like meat processing, where hygiene is critical, automated systems can handle raw materials without introducing pathogens. Additionally, automated cleaning systems (CIP - Clean-in-Place) ensure that equipment is sanitized thoroughly and consistently, complying with health regulations.

Compliance with standards such as HACCP (Hazard Analysis Critical Control Point) is easier to achieve with automation, as systems can continuously monitor critical control points and generate detailed logs for audits. This transparency builds trust with regulators and consumers alike.

Гибкость и адаптивность

Modern automated systems are designed to be flexible, allowing manufacturers to quickly adapt to changing market demands. For example, modular automation solutions enable easy reconfiguration of production lines for new products or packaging styles. This agility is essential in today's fast-paced market, where trends can shift rapidly.

Furthermore, automation supports customization, such as producing limited-edition items or personalized products. By leveraging data and AI, companies can tailor their offerings to individual consumer preferences, opening up new revenue streams.

Реальные примеры и case studies

To illustrate the impact of automation, let's look at some real-world examples from the food industry.

Пример 1: Автоматизация в молочной промышленности

A leading dairy company implemented an automated processing line that includes robotic milking systems, automated pasteurization, and packaging. The results were impressive: a 30% increase in production efficiency, a 20% reduction in labor costs, and a significant improvement in product consistency. The automated system also ensured better traceability, with sensors tracking each batch from farm to table, enhancing safety and compliance.

Пример 2: Роботизация в мясопереработке

In a meat processing plant, the introduction of robotic cutters and sorters led to a 25% higher yield by making more precise cuts and reducing waste. The robots were equipped with AI vision systems to identify optimal cutting points, which human workers might miss. This not improved efficiency but also worker safety by reducing exposure to sharp tools and repetitive strain injuries.

Пример 3: IoT в управлении цепочкой поставок

A global snack manufacturer integrated IoT sensors into its supply chain to monitor temperature and humidity during transportation. This allowed them to prevent spoilage and reduce waste by 15%. The data collected also enabled better inventory management, ensuring that products were fresher when they reached stores, which boosted customer satisfaction.

Будущие тенденции и инновации

The future of automation in food production is bright, with several emerging trends set to further revolutionize the industry.

Расширенное использование AI и big data

AI will continue to evolve, offering more sophisticated predictive capabilities. For example, AI could optimize recipes in real-time based on sensor data, adjusting ingredients to maintain quality despite variations in raw materials. Big data analytics will enable deeper insights into consumer behavior, driving product development and marketing strategies.

Робототехника нового поколения

Next-generation robots will be more dexterous and intelligent, capable of handling complex tasks like assembling prepared meals or performing quality inspections with greater accuracy. Soft robotics, which use flexible materials, will allow for gentle handling of delicate foods, reducing damage and waste.

Устойчивость и экологичность

Automation will play a key role in promoting sustainability. For instance, automated systems can optimize energy use in production facilities, reducing carbon footprints. Additionally, precision agriculture techniques, enabled by automation, can minimize water and pesticide usage, contributing to a more sustainable food system.

Интеграция с blockchain

Blockchain technology can enhance traceability and transparency in the food supply chain. By automating data recording, companies can provide consumers with verifiable information about the origin and journey of their food, building trust and ensuring authenticity.

Заключение

Автоматизация является незаменимым ключом к эффективности и качеству в пищевом производстве. Она не только повышает производительность и снижает costs, но и обеспечивает consistency, безопасность, и гибкость. С развитием технологий, таких как AI, IoT, и робототехника, возможности для автоматизации будут только расширяться, открывая новые горизонты для инноваций и роста.

Для компаний, стремящихся оставаться конкурентоспособными, инвестиции в автоматизацию – это не опция, а необходимость. By embracing these technologies, the food industry can meet the challenges of the future, delivering high-quality products that satisfy consumers and contribute to a sustainable world.

В конечном счете, автоматизация – это больше, чем просто технологии; это transformation towards a smarter, more efficient, and resilient food production ecosystem.