Когда речь заходит о промышленной упаковке, один из самых частых вопросов, который задают предприниматели и логистические специалисты, это: "Какая цена на промышленный упаковочный автомат?" Этот вопрос не так прост, как кажется на первый взгляд. Цена на такое оборудование может варьироваться от нескольких десятков тысяч рублей до миллионов, в зависимости от множества факторов. В этой статье мы подробно разберем, от чего зависит стоимость промышленного упаковочного автомата, какие типы машин существуют, и как выбрать оптимальный вариант для вашего бизнеса. Мы также рассмотрим скрытые затраты, советы по экономии и будущие тренды в этой области. К концу чтения вы будете иметь четкое представление о том, сколько стоит промышленный упаковочный автомат и как принять взвешенное решение при покупке.

Что такое промышленный упаковочный автомат и зачем он нужен?

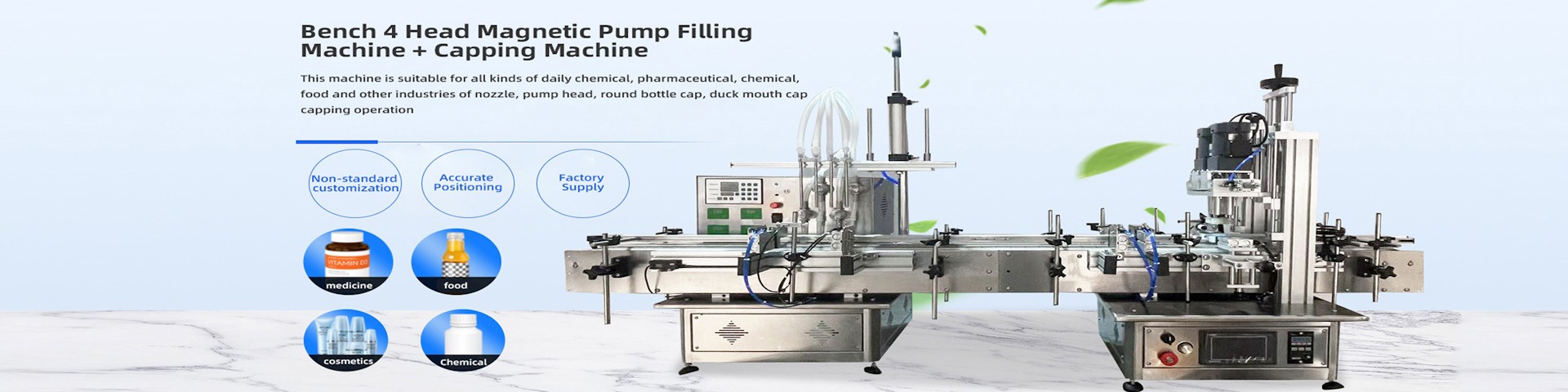

Промышленный упаковочный автомат — это специализированное оборудование, предназначенное для автоматизации процесса упаковки товаров в производственных или складских условиях. Эти машины используются в различных отраслях, таких как пищевая промышленность, фармацевтика, электроника и логистика, чтобы повысить эффективность, снизить затраты на труд и обеспечить consistency упаковки. Основные функции включают в себя формирование, заполнение и герметизацию упаковки, а также маркировку и паллетирование. Цена на такой автомат напрямую связана с его capabilities: более advanced модели с higher throughput и дополнительными features будут стоить дороже. Например, простой автомат для упаковки мелких items может обойтись в 50,000 рублей, в то время как fully automated line для крупного производства может превышать 5 миллионов рублей. Understanding these basics is crucial before diving into cost details.

Factors Influencing the Price of Industrial Packaging Automats

The price of an industrial packaging automaton is influenced by a multitude of factors, each playing a significant role in the final cost. Firstly, the type and complexity of the machine are paramount. Simple machines like stretch wrappers or bag sealers are generally cheaper, ranging from 30,000 to 200,000 rubles, whereas complex systems such as robotic palletizers or integrated packaging lines can cost from 500,000 to over 10 million rubles. Secondly, the brand and origin affect price; European or American brands like Bosch or Krones tend to be more expensive due to higher quality and advanced technology, often costing 20-50% more than Asian alternatives like Chinese machines, which might start from 100,000 rubles but could have lower reliability. Thirdly, production capacity and speed are key determinants. A machine with a high output of 100 packages per minute will be priced higher than one with 20 packages per minute, as it requires more robust components and engineering. Additionally, customization adds cost; if you need specific features like special sealing, labeling, or compatibility with unique products, expect to pay 10-30% extra. Material of construction also matters; stainless steel machines for food or pharmaceutical use are pricier than those made from standard materials, potentially adding 15-25% to the base price. Lastly, after-sales support, warranty, and maintenance services can influence the overall cost, with comprehensive service packages increasing the initial investment but reducing long-term expenses. By considering these factors, businesses can better estimate the price range and avoid surprises.

Types of Industrial Packaging Automats and Their Price Ranges

Industrial packaging automats come in various types, each suited to different applications and budget levels. Let's explore the common categories and their typical price ranges in rubles. First, vertical form-fill-seal (VFFS) machines are popular for packaging powders, granules, or liquids into bags; these can cost from 100,000 to 1,000,000 rubles depending on speed and features. For example, a basic VFFS machine might be around 150,000 rubles, while a high-speed model with multi-lane capabilities could reach 800,000 rubles. Second, horizontal wrapping machines, used for products like newspapers or confectionery, range from 200,000 to 2,000,000 rubles, with automated versions at the higher end. Third, pallet wrapping machines are essential for securing loads on pallets; manual ones start at 20,000 rubles, semi-automatic at 50,000-150,000 rubles, and fully automatic robotic wrappers can cost 500,000-3,000,000 rubles. Fourth, cartoning machines for boxing products vary widely: simple models cost 300,000-700,000 rubles, while complex ones with intricate folding mechanisms may exceed 2,000,000 rubles. Fifth, labeling machines add another layer; basic models are 50,000-200,000 rubles, whereas advanced systems with vision inspection can hit 1,000,000 rubles. Additionally, integrated systems that combine multiple functions, such as packaging and palletizing, command premium prices from 2,000,000 to 10,000,000 rubles or more. It's important to note that these prices are estimates and can fluctuate based on market conditions, brand, and customization. By understanding the types, you can narrow down options that fit your budget and needs.

How to Choose the Right Packaging Automat Based on Price and Needs

Selecting the appropriate industrial packaging automaton involves balancing price with operational requirements to ensure a worthwhile investment. Start by assessing your production volume and speed needs. If you have low to medium output, a cheaper machine in the 100,000-500,000 ruble range might suffice, but for high-volume operations, investing 1,000,000 rubles or more in a faster, more reliable model could pay off through increased efficiency. Next, consider the type of products you handle; fragile or irregularly shaped items may require specialized machines, which could add 20-40% to the cost. For instance, a standard VFFS machine for granules might cost 200,000 rubles, but one designed for delicate electronics could be 300,000 rubles. Also, evaluate the total cost of ownership, not just the purchase price. Cheaper machines might have higher maintenance costs or shorter lifespans, so factor in expenses for spare parts, energy consumption, and potential downtime. A machine priced at 500,000 rubles with low operating costs might be better than one at 400,000 rubles that requires frequent repairs. Additionally, think about scalability; if you plan to expand, opting for a moderately priced machine with upgrade options (e.g., 600,000 rubles with modular add-ons) can save money long-term compared to buying a new one later. Don't forget to get quotes from multiple suppliers and negotiate; prices can often be reduced by 5-15% through bargaining or purchasing during promotions. Lastly, consider leasing or financing options if the upfront cost is prohibitive; this can spread payments over time and make higher-end machines more accessible. By taking a holistic approach, you can find a machine that offers the best value for your specific situation.

Hidden Costs Associated with Industrial Packaging Automats

Beyond the initial purchase price, there are several hidden costs that businesses should be aware of when investing in an industrial packaging automaton. These can significantly impact the overall expenditure and should be factored into the budgeting process. First, installation and setup costs can add 10-20% to the base price; for example, if a machine costs 1,000,000 rubles, installation by technicians might require an additional 100,000-200,000 rubles, especially if structural modifications to the facility are needed. Second, training for operators is essential; budget 20,000-50,000 rubles for initial training sessions to ensure safe and efficient use. Third, maintenance and spare parts are ongoing expenses; annual maintenance contracts can cost 5-15% of the machine's price, so for a 500,000 ruble machine, expect to pay 25,000-75,000 rubles per year. Fourth, energy consumption varies by machine type; high-speed automats may use more electricity, adding 10,000-30,000 rubles annually to operational costs. Fifth, software updates and integration with existing systems (e.g., ERP) might incur fees, typically 10,000-50,000 rubles initially and periodically. Sixth, potential downtime during repairs can lead to lost production, which is hard to quantify but should be mitigated with reliable equipment. Seventh, compliance with regulations, such as safety standards or environmental norms, may require additional investments in modifications or certifications, costing 10,000-100,000 rubles depending on the region. By anticipating these hidden costs, you can avoid budget overruns and ensure a smooth operation. It's advisable to discuss these with suppliers during the purchasing process to get a comprehensive cost estimate.

Tips for Saving Money on Industrial Packaging Automats

While industrial packaging automats represent a significant investment, there are strategies to reduce costs without compromising on quality. First, consider buying used or refurbished machines; these can be 30-50% cheaper than new ones. For instance, a used VFFS machine that originally cost 300,000 rubles might be available for 150,000-210,000 rubles, but ensure it comes with a warranty and has been inspected for reliability. Second, opt for standard models instead of customized ones; customization can increase prices by 10-30%, so if a standard machine meets your needs, you could save substantially. For example, choosing a off-the-shelf pallet wrapper at 100,000 rubles instead of a custom one at 130,000 rubles. Third, bundle purchases with other equipment or negotiate package deals with suppliers; this might yield discounts of 5-15%. Fourth, invest in energy-efficient models to lower long-term operational costs; though they might have a higher upfront price, the savings on electricity can offset this over time. Fifth, perform regular maintenance yourself if possible, rather than relying on expensive service contracts, but only if you have the expertise to avoid damages. Sixth, compare prices from different regions; importing a machine from Asia might be cheaper due to lower manufacturing costs, but factor in shipping and import duties. Seventh, take advantage of government incentives or subsidies for automation equipment, which could reduce the net cost by 10-20% in some countries. By implementing these tips, you can make the purchase more affordable and maximize your return on investment.

Future Trends in Industrial Packaging Automation and Price Implications

The field of industrial packaging automation is evolving rapidly, with trends that will influence future prices and capabilities. Understanding these can help businesses plan ahead and make informed decisions. Firstly, the integration of IoT and smart technologies is becoming standard; future machines will be more connected, allowing for real-time monitoring and predictive maintenance. This might increase initial costs by 10-20% due to advanced sensors and software, but could reduce long-term expenses by minimizing downtime. For example, a smart packaging automaton priced at 1,200,000 rubles today might offer better efficiency than a traditional one at 1,000,000 rubles. Secondly, sustainability is a growing focus; machines designed for eco-friendly packaging materials or energy savings may cost more upfront but align with regulatory demands and consumer preferences, potentially adding 5-15% to the price. Thirdly, robotics and AI are enhancing automation; collaborative robots (cobots) for packaging tasks are becoming more affordable, with prices dropping from millions to hundreds of thousands of rubles, making high automation accessible to smaller businesses. Fourth, modular and scalable systems are on the rise, allowing businesses to start with a basic setup and expand as needed, which can spread costs over time. Lastly, global supply chain fluctuations might affect prices; for instance, disruptions could lead to higher costs, so locking in prices early or diversifying suppliers is wise. By staying informed about these trends, you can anticipate changes and choose machines that offer future-proof value, even if they require a higher initial investment.

Conclusion: Making an Informed Decision on Price

In conclusion, the question "Какая цена на промышленный упаковочный автомат" does not have a one-size-fits-all answer, as prices vary widely based on type, brand, capacity, and additional factors. From basic machines costing as low as 20,000 rubles to advanced systems exceeding 10 million rubles, the key is to align the investment with your specific needs and budget. By considering the total cost of ownership, hidden expenses, and future trends, businesses can avoid overspending and achieve optimal efficiency. Remember to conduct thorough research, obtain multiple quotes, and leverage cost-saving strategies such as buying used or negotiating deals. Ultimately, a well-chosen industrial packaging automaton can transform your operations, boost productivity, and provide a strong return on investment. If you have further questions or need assistance, consult with experts in the field to guide your decision-making process.